In recent years, with the continuous development of highways and high-speed railways in China, the demand for materials such as concrete is gradually increasing. Therefore, the demand for stabilized soil mixing plants is also gradually increasing. So, what is the composition of a complete set of stabilized soil mixing plants?

Granular material proportioning system.

The granular material batching system of this utility model consists of an electronic belt scale, a bracket, a bucket body, a protective plate, a top plate, an insertion plate, a bucket door adjustment device, etc. The particles fall onto the original aggregate belt conveyor through the belt scale and are then transported to the mixer by the original aggregate belt conveyor. The door adjustment device includes a plug-in door and a screw. Adjust the opening of the material door to control the cross-sectional size of the material flow, and control the size of the material flow together with adjusting the speed of the electronic belt scale. The speed regulating motor is required to work at a medium speed or above.

The second is the powder batching system.

The powder mixing system consists of a powder silo, a frame, a speed regulating screw conveyor, and a screw scale. The speed controlled powder is transported from the powder hopper to the spiral scale by the screw conveyor and enters the mixer. Both the upper and lower powder hoppers are equipped with level gauges to control the feeding of materials from the cement silo by the screw conveyor.

The third is the transportation system for materials.

The raw material conveying system consists of a raw aggregate belt conveyor, a finished product belt conveyor, and a screw conveyor. The original aggregate belt conveyor and the finished belt conveyor are both composed of a frame, an electric drum, a reversing drum, a groove type roller group, a flat roller group, a regular transport belt group, a roller group, roller legs, and a cleaner. The threaded conveyor is composed of transmission device, threaded pipe, spiral shaft, front and rear supports, feeding port, canvas cover and other parts.

The fourth is the water supply system.

The water supply system of the soil stabilization station consists of a water tank, water pump, solenoid valve, throttle valve, turbine flow sensor, filter, sewer pipe, pipeline and other parts. The principle of water measurement is that when water passes through the turbine flow sensor, the turbine flow sensor generates a signal, which is fed back to the control center of the system. The system then generates a control signal for frequency adjustment, thereby controlling the pump speed and achieving automatic compensation function.

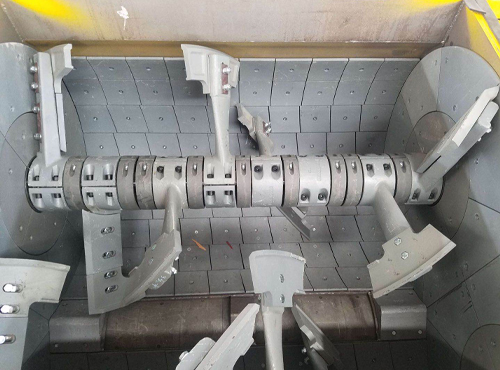

Five is the mixer.

The mixing host of the soil stabilization station consists of a transmission device, a mixing tank, a mixing device, a cover, a gear cover, etc. The mixer is driven by two coaxial cylindrical gear reducers to rotate in opposite directions at a constant speed. Each mixing shaft is equipped with mixing blades at a certain angle to the mixing shaft. By pushing the inclined blades, the material in the mixing tank moves forward and is unloaded from the other end.

A stable soil mixing plant is roughly composed of the above aspects, and the specific configuration is customized and produced according to the actual needs of users. So, before deciding to build a stable soil mixing plant, one must first consider their own needs.

Address: No. 818, Jingshi Road, Jinan, China

Tel: 0086-531-87453566

Fax: 0086-531-87453566

Postal Code: 250306

Email: sdjkgroup@163.com

jianke3566@163.com